Mevisa Components

Precision Machines and Custom Industrial Solutions

We boost your company’s productivity with more than 25 years of experience, specialized technology, and certified quality.

About Us

Who we are

We are a Mexican company established in 1996 with experience in the manufacturing of industrial parts and components. Our growth has been driven by the quality, efficiency, and satisfaction of our customers in Mexico, the United States, Canada, and Brazil.

We offer integrated processes in a single location, including custom cutting, special welding, and precise delivery times, meeting the highest quality standards. Our combination of technology, experience, and commitment to excellence positions us as the ideal supplier in the industry.

Services

Technology, experience and quality at the service of your company

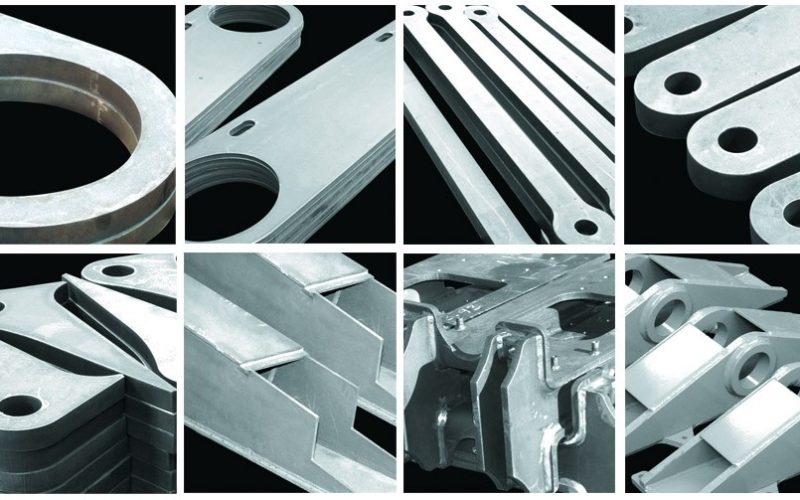

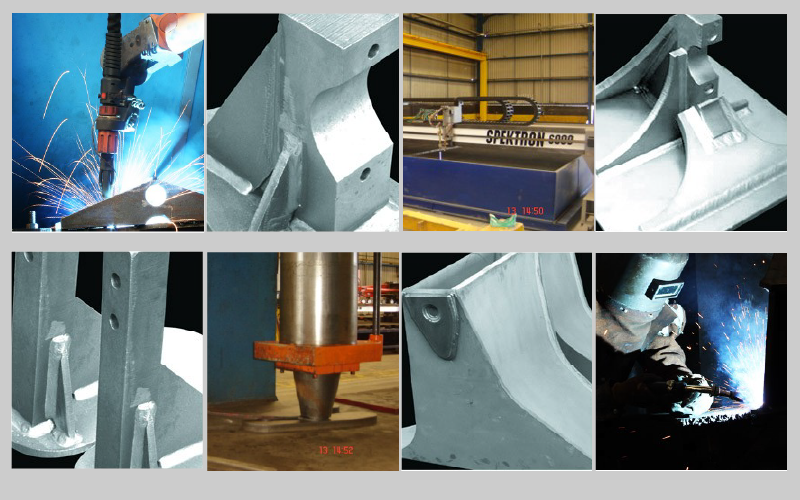

Parts Manufacturing

Plate cutting

Oxy-cutting, plasma or laser

Precision adjustment

Oxy-fuel beveling

Bending and straightening with a press

Sand and shot blast

Plucking

Welding

Robotic welding

Punching and laser punching

Mechanical assembly

Machining

Products

Highest Quality and Precision models on the market.

We offer a variety of products, including diverging valves, rotary valves, and vacuum pumps, ensuring the highest quality in materials and workmanship, all at competitive prices.

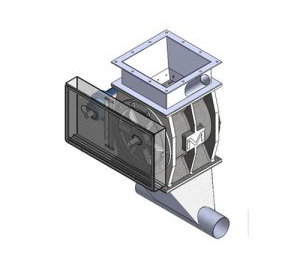

Divergent valve

Open-channel valves designed to eliminate pressure drops, ideal for abrasive, granular, fine, or pellet materials in pressure and vacuum systems. Manufactured in gray or nodular iron, stainless steel, or aluminum, with a 30° angle at the inlet and outlet ports. They can be operated manually or by a PLC-controlled pneumatic actuator.

Blowers +

vacuum pump

At Mevisa, we manufacture blowing equipment designed to meet the needs of air flow, vacuum generation, and gas pumping in industrial processes. Our blowers guarantee high quality, durability, and superior performance compared to similar equipment, providing reliability and efficiency in every installation.

Rotary valve

Valves made of cast iron, stainless steel, and welded construction, designed for light, normal, and heavy-duty applications under gravity and differential pressures up to 12 PSI. They incorporate high-capacity tapered bearings (except in light duty) and operate in three stages with a gearbox and chain drive, optimized for continuous operation.

Our Values

The Philosophy at Mevisa

Responsibility in every delivery

Commitment to quality

Honesty in our service

Teamwork

Innovation

Advantages

Why are we the best at what we do?

Awards and Recognitions

We operate under international quality and control standards, following specifications such as the Welding Procedure Specification (WPS) and the Procedure Qualification Record (PQR) for SMAW, GMAW, and FCAW welding.

Throughout our history, we have maintained a strong commitment to quality. As a result, our Quality System is certified under the ISO 9001:2015 standard, earning us recognition from Caterpillar with the ‘Weld Quality Program – 7 Steps to Excellence’ award.

Infrastructure

7500 square meters of covered space allow for ample productions and storage capacity, our cutting line has 60 meters, 1500 tons per month and 2000 square meters of yard.

Work force

Our highly trained team works with excellence to fulfill our mission and exceed our customers' expectations.

We are committed to job and financial stability, as well as the personal and professional growth of our employees, providing ongoing training for their development.

Our welders are certified by the CWI (Certified Welding Inspector).

Equipment and capabilities

We have high-quality equipment to ensure satisfactory production.

Continuous Improvement

We constantly invest in cutting-edge technology to ensure precision in meeting our customers' demands, providing innovative solutions and exceptional service.

Our continuous improvement approach follows the Six Sigma methodology, allowing us to achieve near-perfect product quality. Thanks to this, we meet the highest standards of demanding industries such as food, cement, steel, glass, chemical, oil, and general processing industries.

Contact

Let's talk about your next industrial project

- amedina@mevisa.com.mx

- 81 82 62 55 00

- Carretera Super Manzana km 2 Dulces Nombres, N.L., C.P. 66650